Product description

As the regulation and closure devices using double eccentric butterfly valve, also known as the high performance butterfly valve, mainly used in waterworks, power plants, steel smelting, chemical, water fountain engineering, environmental facilities, etc. the drainage system, especially for the waterway pipe. Compared with the midline butterfly valve, double eccentric butterfly valve is more resistant to high pressure, long life, good stability. Compared with other valves, the smaller the diameter of the material, the lighter, the cost is lower.

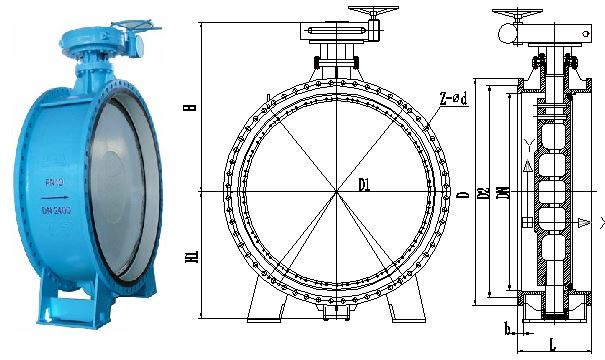

Main connection and dimensions(PN10)

nominal diameter

Main dimensions and connection dimensions(mm)

valve size mm

flange connection size mm

L

H1

H

D

D1

D2

b

f

z-Φd

250

165

193

416

395

350

314

26

3

12-Φ22

300

178

244

378

445

400

362

26

4

12-Φ22

350

190

276

505

505

460

422

26

4

16-Φ22

400

216

307

570

565

515

473

26

4

16-Φ26

450

222

332

600

615

565

523

28

4

20-Φ26

500

229

364

640

670

620

578

28

4

20-Φ26

600

267

424

760

780

725

677

34

5

20-Φ30

700

292

484

800

895

840

792

35

5

24-Φ30

800

318

546

878

1015

950

899

38

5

24-Φ33

900

330

605

945

1115

1050

999

38

5

28-Φ33

1000

410

700

1060

1230

1160

1106

44

5

28-Φ36

1200

470

785

1195

1455

1380

1323

55

5

32-Φ39

1400

530

910

1360

1670

1590

1520

65

5

36-Φ42

1600

600

1043

1516

1915

1820

1740

75

5

40-Φ48

1800

670

1128

1660

2115

2020

1940

85

5

44-Φ48

2000

760

1290

1850

2325

2230

2150

90

5

48-Φ48

2200

800

1372

1934

2250

2440

2368

58

5

52-Φ56

2400

900

1535

2046

2760

2650

2564

70

5

56-Φ56

-

Main parts material

material code

Valve body, valve cover

valve plate

valve seat

sealing ring

valve stem

filler

z

HT200 Gray cast iron

Gray cast iron

HT200+Copper / stainless steel

rubber

20Cr13

graphite

Q

QT450 Nodular graphite cast iron

Nodular graphite cast iron

QT450+Copper / stainless steel

rubber

20Cr13

graphite

C

WCB carbon steel

carbon steel

WCB+Copper / stainless steel/Cemented carbide

rubber

20Cr13

graphite

P

CF8 (304 )stainless steel

stainless steel

stainless steel

rubber

304

PTFE

R

CF8M (316) stainless steel

stainless steel

stainless steel

rubber

316

PTFE

PL

CF3 (304 L)stainless steel

stainless steel

stainless steel

rubber

304L

PTFE

RL

CF3M (316L)stainless steel

stainless steel

stainless steel

rubber

316L

PTFE

-

Nickel chromium cast iron

Nickel chromium cast iron

Nickel chromium cast iron+316L

rubber

316L

PTFE

Other special materials, our company can also be tailored to customer needs.

-

Main performance characteristics

Shell material

Applicable medium

Applicable temperature(℃)

Gray cast iron(Z)

Water, air, oil

≤80

Nodular graphite cast iron(Q)

Water, air, oil

≤80

carbon steel(C type)

Water, air, oil

≤80

Ci Ni Ti(P type)

Nitric acid

≤80

Ci Ni Mo Ti Steel(R type)

Nitric acid

≤80

Nickel chromium cast iron

seawater

≤80

Nominal pressure PN(MPa)

shell

Test pressure(MPa)

seal(liqiud)

seal(gas)

0.6

0.9

0.66

0.6

1.0

1.5

1.1

0.6

1.6

2.4

1.8

0.6

2.5

3.8

2.8

0.6

- $Column4$

- $Column5$

More Products