Product description

Swing check valve, also known as a one-way valve or check valve, its role is to prevent the media back in the pipeline. Opening and closing pieces by medium flow and power to open or close, in order to prevent the media back valve is called the check valve. Check valves are automatic valves, mainly for the medium one-way flow of the pipeline, only to allow the media to flow in one direction, in order to prevent the occurrence of accidents. This type of valve in the pipeline should generally be installed horizontally. Can be applied to water, steam, oil, nitric acid, acetic acid, strong oxidizing medium and urea and other media. Mainly used in petroleum, chemical, pharmaceutical, fertilizer, power and other pipelines.

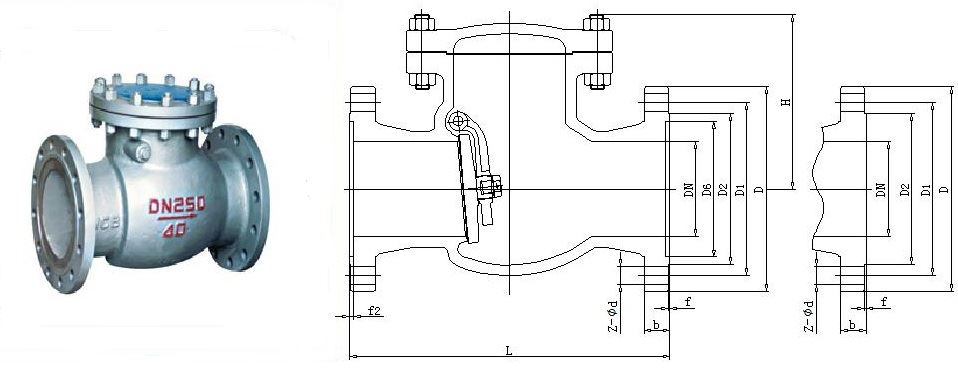

Main connection and dimensions(PN25)

nominal diameter

Main connection and dimensions

Body connecting dimensions

flange connecting dimensions

L

H

D

D1

D2

b

f

Z-Φd

50

230

160

160

125

100

20

3

4-18

65

290

175

180

145

120

22

3

8-18

80

310

185

195

160

135

22

3

8-18

100

350

220

230

190

160

24

3

8-23

125

400

248

270

220

188

28

3

8-25

150

480

276

300

250

218

30

3

8-25

200

550

350

360

310

278

34

3

12-25

250

650

410

425

370

332

36

3

12-30

300

750

430

485

430

390

40

4

16-30

350

850

518

550

490

448

44

4

16-34

400

950

560

610

550

505

48

4

16-34

500

1150

618

730

660

610

52

4

20-41

main connecting and dimensions(PN40)

nominal diameter

main connecting and dimensions

valve connection size

flange connnection size

L

H

D

D1

D2

D6

b

f

f2

Z-Φd

50

230

169

160

125

100

88

20

3

4

4-18

65

290

173

180

145

120

110

22

3

4

8-18

80

310

185

195

160

135

121

22

3

4

8-18

100

350

220

230

190

160

150

24

3

4.5

8-23

125

400

248

270

220

188

176

28

3

4.5

8-25

150

480

270

300

250

218

204

30

3

4.5

8-25

200

550

342

375

320

282

260

38

3

4.5

12-30

250

650

401

445

385

345

313

42

3

4.5

12-34

300

750

423

510

450

408

364

46

4

4.5

16-34

350

850

455

570

510

465

422

52

4

5

16-34

400

950

510

655

585

535

474

58

4

5

16-41

main connection and outside size(PN64)

nominal diameter

main connection and outside size

body connection size

flange connnection size

L

H

D

D1

D2

D6

b

f

f2

Z-Φd

50

300

177

175

135

105

88

26

3

4

4-23

65

340

197

200

160

130

110

28

3

4

8-23

80

380

212

210

170

140

121

30

3

4

8-23

100

430

248

250

200

168

150

32

3

4.5

8-25

125

500

296

295

240

202

176

36

3

4.5

8-30

150

550

330

340

280

240

204

38

3

4.5

8-34

200

650

385

405

345

300

260

44

3

4.5

12-34

250

775

445

470

400

352

313

48

3

4.5

12-41

300

900

474

530

460

412

364

54

4

4.5

16-41

350

1025

514

595

525

475

422

66

4

5

16-41

400

1150

616

670

585

525

474

36

4

5

16-48

main connection and outside size(PN100)

nominal diameter

main connection and outside size

valve body connection size

flange connection size

L

H

D

D1

D2

D6

b

f

f2

Z-Φd

50

300

210

195

145

112

88

28

3

4

4-Φ25

65

340

227

220

170

138

110

32

3

4

8-Φ25

80

380

235

230

180

148

121

34

3

4

8-Φ25

100

430

274

265

210

172

150

38

3

4

8-Φ30

150

550

340

350

290

250

204

46

3

4.5

12-Φ34

200

650

374

430

360

312

260

54

3

4.5

12-Φ41

250

775

440

500

430

382

313

60

3

4.5

12-Φ41

300

900

505

585

500

442

364

70

4

4.5

16-Φ48

Main Parts Material

Material CODE

Valve body, valve cover

valve clack Swing arm

shim

C

WCB carbon steel

WCB+hard alloy or stainless steel

WCB carbon steel

graphite+304

P

CF8(304) stainless steel

stainless steel

CF8(304) stainless steel

PTFE

R

CF8M(316)stainless steel

stainless steel

CF8M(316)stainless steel

PTFE

I

WC6 Cr Mo steel

Alloy steel + hard alloy

WC6 Cr Mo steel

graphite+304

V

WC9 Cr Mo steel

Alloy steel + hard alloy

WC9 Cr Mo steel

graphite+304

Other special materials, our company can also be tailored to customer needs.

Material CODE

Valve body, valve cover

valve clack

Swing arm

shim

C

WCB carbon steel

WCB+hard alloy or stainless steel

WCB carbon steel

graphite+304

P

CF8(304) stainless steel

stainless steel

CF8(304) stainless steel

PTFE

R

CF8M(316) stainless steel

stainless steel

CF8M(316) stainless steel

PTFE

I

WC6 Cr Mo steel

Alloy steel + hard alloy

WC6 Cr Mo steel

graphite+304

V

WC9 Cr Mo steel

vAlloy steel + hard alloy WC9 Cr Mo steel

graphite+304

Other special materials, our company can also be tailored to customer needs.

shell material

Applicable medium

Applicable temperature(℃)

carbon steel(C type)

Water, steam, oil

≤425

Ci Ni Ti(P type)

Nitric acid

≤150

Ci Ni Mo Ti Steel(R type)

Acetic acid

≤150

Cr Mo steel(I type)

Water, steam, oil

≤550

Nominal pressure PN(MPa)

housing(MPa)

Test pressure(MPa)

Seal (liquid)(MPa)

Seal (gas)(MPa)

1.6

2.4

1.8

0.6

2.5

3.8

2.8

0.6

4

6

4.4

0.6

6.4

9.6

7

0.6

10

15

11

0.6

- Implementation standards:

Design standard: GB/T12236

Structure length: GB/T12221

Connecting flange: JB/T79, GB/T9113, HG/T20592, HG/T20615

Experiment and test: JB/T9092, GB/T13927

Pressure - temperature: GB/T9131

Product label: GB/T12220

- Storage and maintenance

1 the valve must be kept in a dry, ventilated room.

2 the storage period of the valve, the valve should be closed and fixed, both ends of the flange should be closed.

3 during the storage of the valve, the surface of the machine is easy to be removed.

4 long-term storage of the valve should be regularly checked, timely protection.

Installation and maintenance

1 the installation position of the valve is not limited, usually installed in horizontal pipeline, can also be installed in the vertical pipe or inclined pipeline, but it is convenient for maintenance.

2 must be carefully checked before installation, the valve plate is marked and consistent with the requirement and condition.

3 when installing, should check the inner cavity, remove the valve flap fixing device, try to check the sealing surface of the valve flap, and clean.

4.. Lifting the valve before, should check whether it has been tightening screw ring.

5 installation should pay special attention to media flow, should make the normal flow direction and the direction of the arrow on the valve body on the direction of the arrow is consistent, otherwise it will cut off the normal flow of the media.

6 when installing, tighten the connecting bolts evenly and symmetrically.

More Products