The product description

Welding connection of valve is suitable for the nominal pressure PN16.0 32.0 Mpa, the working temperature of 540 ℃ or less oil, chemical industry, hydropower and thermal power plant all kinds of the pipeline system, cut off or connect pipe medium. Applicable medium such as water, oil, acid medium. Operation manual and gear drive, electric, etc.

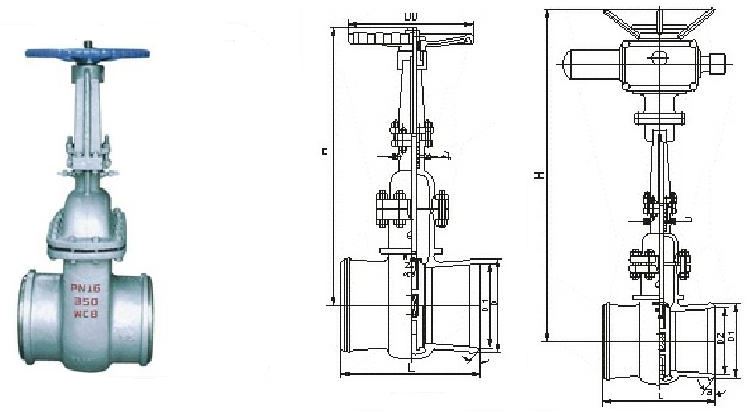

The main connection and overall dimensions

Nominal diameter

L

a

H

PN1.6(MPa)

PN2.5(MPa)

D1

D2

Denso device

D1

D2

Denso device

50

250

37°30′

620

58

50

DZW10

64

49

ZB10

65

270

37°30′

714

75

65

DZW10

82

67

ZB10

80

280

37°30′

765

91

79

DZW10

95

77

ZB10

100

300

37°30′

840

110

97

DZW15

117

101

ZB15

125

325

37°30′

852

136

121

DZW15

144

126

ZB20

150

350

37°30′

875

163

146

DZW20I

172

158

ZB20

200

400

37°30′

1015

223

202

DZW20

223

202

ZB25

250

450

37°30′

1125

278

254

DZW30

278

254

ZB25

300

500

37°30′

1371

330

305

DZW45

330

305

ZC45

350

550

37°30′

1485

382

352

DZW60

382

352

ZC60

400

600

37°30′

1890

432

399

DZW60

432

399

ZC90

450

650

37°30′

1989

485

451

DZW90

485

451

ZC120

500

700

37°30′

2041

535

501

DZW120

535

499

ZC120

600

800

37°30′

2285

636

601

DZW180

636

599

ZC180

700

900

37°30′

2347

726

691

DZW250

726

689

ZC250

800

1000

37°30′

2593

826

791

DZW350

826

789

ZC350

The main connection and overall dimensions

Nominal diameter

L

D

a

PN4.0(MPa)

PN6.4MPa)

PN10.0(MPa)

D1

H

Electric actuator

D1

H

Electric actuator

D1

H

Electric actuator

50

280

64

37°30′

49

620

DZW10

50

622

DZW10

49

622

ZB10

65

310

83

37°30′

67

714

DZW10

66

718

DZW15

64

718

ZB15

80

350

96

37°30′

79

767

DZW15

77

770

DZW20I

75

770

ZB20

100

400

117

37°30′

101

845

DZW20I

99

845

DZW20I

97

845

ZB25

125

450

144

37°30′

126

852

DZW20I

129

852

DZW30

125

852

ZB25

150

550

172

37°30′

152

875

DZW30

150

875

DZW30

145

965

ZC45

200

650

223

37°30′

200

1015

DZW30

198

1105

DZW45

190

1105

ZC60

250

750

278

37°30′

252

1215

DZW45

246

1215

DZW60

236

1237

ZC90

300

850

330

37°30′

302

1371

DZW60

294

1424

DZW90I

282

1424

ZC120

350

950

382

37°30′

350

1507

DZW90I

342

1507

DZW120I

334

1670

ZC180

400

1050

432

37°30′

397

1912

DZW120

387

2075

DZW180

377

2075

ZC250

Note: PN1.6 (16) valve allows as PN1.0 (10) pressure level to choose.

The main connection and overall dimensions

Nominal diameter

L

a

H

PN1.6(MPa)

PN2.5(MPa)

D1

D2

Denso device

D1

D2

Denso device

50

250

37°30′

620

58

50

DZW10

64

49

ZB10

65

270

37°30′

714

75

65

DZW10

82

67

ZB10

80

280

37°30′

765

91

79

DZW10

95

77

ZB10

100

300

37°30′

840

110

97

DZW15

117

101

ZB15

125

325

37°30′

852

136

121

DZW15

144

126

ZB20

150

350

37°30′

875

163

146

DZW20I

172

158

ZB20

200

400

37°30′

1015

223

202

DZW20

223

202

ZB25

250

450

37°30′

1125

278

254

DZW30

278

254

ZB25

300

500

37°30′

1371

330

305

DZW45

330

305

ZC45

350

550

37°30′

1485

382

352

DZW60

382

352

ZC60

400

600

37°30′

1890

432

399

DZW60

432

399

ZC90

450

650

37°30′

1989

485

451

DZW90

485

451

ZC120

500

700

37°30′

2041

535

501

DZW120

535

499

ZC120

600

800

37°30′

2285

636

601

DZW180

636

599

ZC180

700

900

37°30′

2347

726

691

DZW250

726

689

ZC250

800

1000

37°30′

2593

826

791

DZW350

826

789

ZC350

The main connection and overall dimensions

nominal

size

L

D

a

PN4.0(MPa)

PN6.4MPa)

PN10.0(MPa)

D1

H

Electric actuator

D1

H

Electric actuator

D1

H

Electric actuator

50

280

64

37°30′

49

620

DZW10

50

622

DZW10

49

622

ZB10

65

310

83

37°30′

67

714

DZW10

66

718

DZW15

64

718

ZB15

80

350

96

37°30′

79

767

DZW15

77

770

DZW20I

75

770

ZB20

100

400

117

37°30′

101

845

DZW20I

99

845

DZW20I

97

845

ZB25

125

450

144

37°30′

126

852

DZW20I

129

852

DZW30

125

852

ZB25

150

550

172

37°30′

152

875

DZW30

150

875

DZW30

145

965

ZC45

200

650

223

37°30′

200

1015

DZW30

198

1105

DZW45

190

1105

ZC60

250

750

278

37°30′

252

1215

DZW45

246

1215

DZW60

236

1237

ZC90

300

850

330

37°30′

302

1371

DZW60

294

1424

DZW90I

282

1424

ZC120

350

950

382

37°30′

350

1507

DZW90I

342

1507

DZW120I

334

1670

ZC180

400

1050

432

37°30′

397

1912

DZW120

387

2075

DZW180

377

2075

ZC250

Note: PN1.6 (16) valve allows as PN1.0 (10) pressure level to choose.

The major parts material

Material code

valve body

valve plate The piston

The valve stem

Four open loop

packing

Stem nut

C

WCB Carbon steel

WCB

A105

20Cr13

A105

graphite

ZQAL9-4

I

WC6 Chrome molybdenum steel

WC6

F11

38CrMoAL

F11

graphite

ZQAL9-4

V

WC9 Chrome molybdenum steel

WC9

F22

25Cr2MoVA

F22

graphite

ZQAL9-4

Other special material our company can also be customized according to customer's requirements.

The performance specification

Shell material

Applicable medium

Applicable temperature(℃)

Carbon steel(C type)

Water, steam, oil

≤425

Chrome molybdenum steel(I、V type)

Water, steam, oil

≤550

Nominal pressure PN(MPa)

shell

Test pressure(MPa)

upper seal

Seal (liquid)

Seal (gas)

1.6

2.4

1.8

0.6

1.8

2.5

3.8

2.8

0.6

2.8

4.0

6

4.4

0.6

4.4

6.4

9.6

7

0.6

7

10

15

11

0.6

11

Execution standard:

Design criteria: JB/T3595

Structure length: GB/T12221

Groove size: JB/T3595

Experiment and test: GB/T13927

Pressure and temperature: GB/T9131 JB/T3595

Product labeling: GB/T12220

Storage maintenance

Valve can be stored in any masking area, but must pay attention to prevent valves are dirty mud or foundation. In at the time of shipment, the valve inlet and outlet are with protection cover. Note before installing the valve, don't to remove the protection cover. Ready to install the valve, the first will protect the end cover, and then check whether connection parts clean. For welding the parts need to clean them with a suitable solution, such as acetone or alcohol. Don't use contain fluoride and chloride solution.

Installation and maintenance

1. Before installation, must carefully check whether mark and nameplate of valve is consistent with working condition requirements.

(2) hand wheel, lever operation of pipe cut-off valve can be installed in any position.

3. The handwheel, handle and wei mechanism, does not allow for lifting.

4. The flow of medium should be consistent with the direction arrow shown in the body.

More Products